Gallery

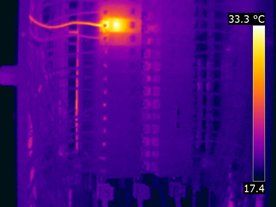

Electrical and Mechanical

Overloaded circuits/breakers, switches or fuses, loose/corroded connections, etc. for preventative maintenance, safety and/or energy efficiency.

Some people may ask themselves why is it important to have a thermal scan completed on electrical or mechanical systems. An overloaded breaker or loose connection (to name a few) can cause overheating, which potentially can cause a fire. You can check with your insurance provider to see if they will provide you a discount when a thermal scan is completed. Infrared Thermal Imaging is an excellent condition monitoring tool to assist in the reduction of maintenance costs on mechanical equipment. Having a Meltech Thermal Imaging Inc. Certified Thermographer perform a preventative maintenance scan on a regular basis can save you valuable time and money.

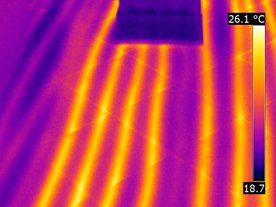

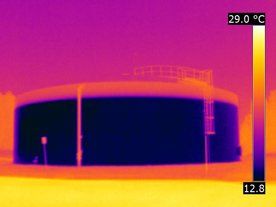

HVAC Operating Systems

Heating systems efficiencies, ventilation ductwork leaks, hydronic or electrical in-floor heating lines locates or breaks, motor windings or lubrications, etc. for preventative maintenance safety and/or energy efficiency.

Most people wouldn’t consider having an HVAC System scan. In order to have the “whole building” approach, the HVAC system is a crucial aspect of the entire building. The indoor environment can help in one’s health and the efficiency of the building. If ignored, the HVAC System could be a costly oversight. Contacting Meltech Thermal Imaging Inc. to perform a simple scan to avoid unscheduled downtime, detect problems quickly without interrupting any services and check for defective equipment while still under the manufacturer’s warranty.

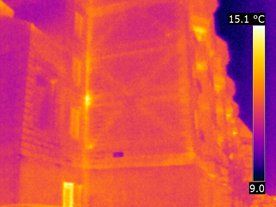

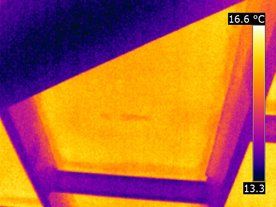

Building Envelope Anomalies

Doors, windows, roofs, walls, floors and foundations for water or air leaks; rodents or insect infestations; insulation voids or damages; possible mould issues and/or energy efficiency.

No matter what you are looking for Meltech Thermal Imaging Inc. can detect any sort of problems that are or may occur within the building envelope. You could experience air/water intrusion within the doors, windows, roofs, floors and foundation. Our services can also detect whether you have insulation voids, potential mould issues and/or energy efficiency problems, or you may be experiencing the unpleasant nuisance of rodents or insect infestations. For commercial applications, we recommend that you have a complete “Base Line” scan on your new building during the commissioning stage.

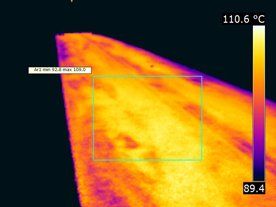

Building Catastrophe Avoidance

Schools, Hotels, Health Care Facilities, Special Care Homes, Nursing Homes, etc.

Meltech Thermal Imaging Inc. specializes in Building Catastrophe Avoidance. Imagine your child’s school being closed because of an electrical fire which could have been avoided by a simple regularly scheduled thermal scan. Mechanical and Electrical breakdowns can be avoided within any production plant or facility. What costs can be associated with avoiding 4, 8, 10 or more hours of breakdowns? Let Meltech Thermal Imaging Inc. help you avoid these circumstances.